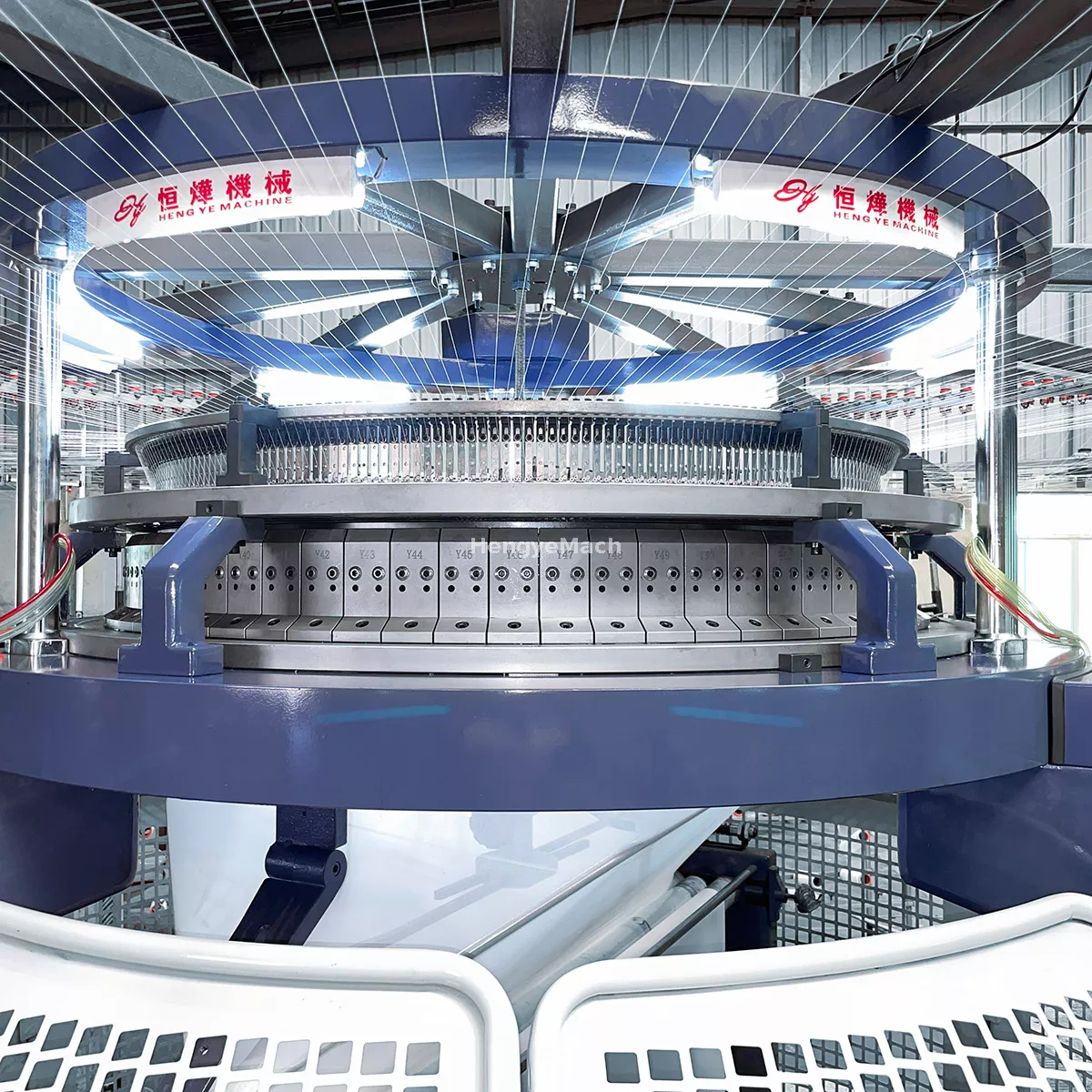

In the dynamic world of textile manufacturing, precision, versatility, and innovation are the cornerstones of success. Hengye, a prominent circular knitting machine manufacturer headquartered in China, has emerged as a global leader by mastering these principles through its cutting-edge double pile circular knitting machine and artificial fur knitting machine lines. Catering to diverse industries—from fashion and home textiles to automotive interiors—Hengye’s plush fabric knitting equipment supplier reputation is built on delivering machines that redefine efficiency and creativity.

Why Hengye Dominates China’s Knitting Machinery Sector

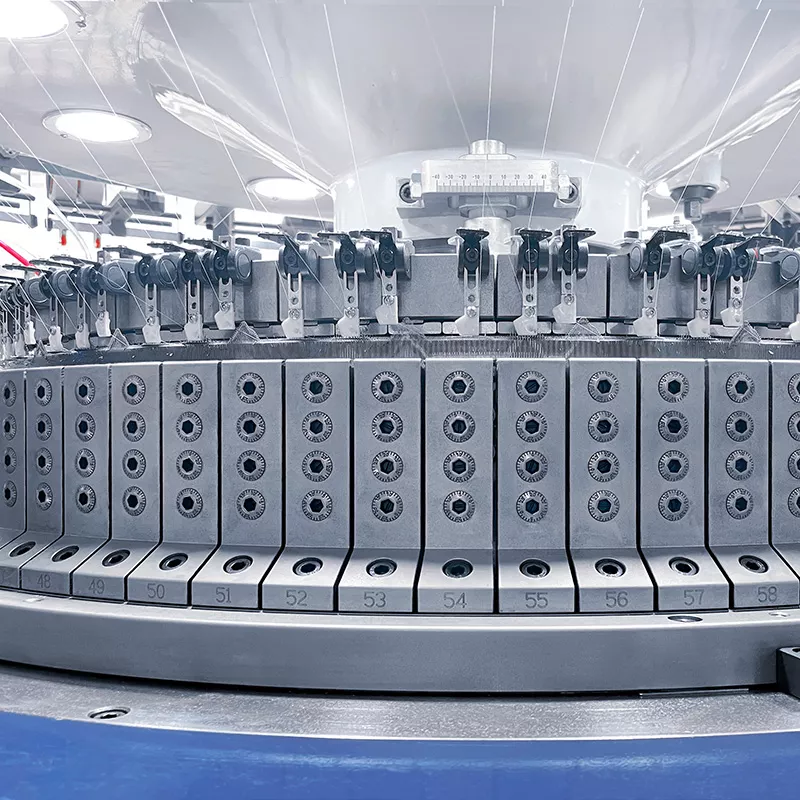

China’s textile machinery industry is fiercely competitive, but Hengye distinguishes itself by prioritizing custom solutions tailored to client needs. Unlike mass-produced alternatives, their double pile circular knitting machine is engineered with modular components, allowing manufacturers to adjust needle counts, gauge sizes, and fabric weights on demand. This flexibility ensures seamless transitions between projects, whether producing luxurious faux fur coats or high-pile upholstery fabrics.

Similarly, Hengye’s artificial fur knitting machine integrates advanced yarn feeding systems and pattern programming software, enabling intricate designs that mimic natural fur textures. By combining automation with precision control, these machines reduce material waste and energy consumption—a critical advantage for eco-conscious brands. As a manufacturer deeply rooted in China’s industrial ecosystem, Hengye leverages local supply chains to keep costs competitive while maintaining global quality standards, making their equipment accessible to startups and large-scale enterprises alike.

Customization: The Heart of Hengye’s Success

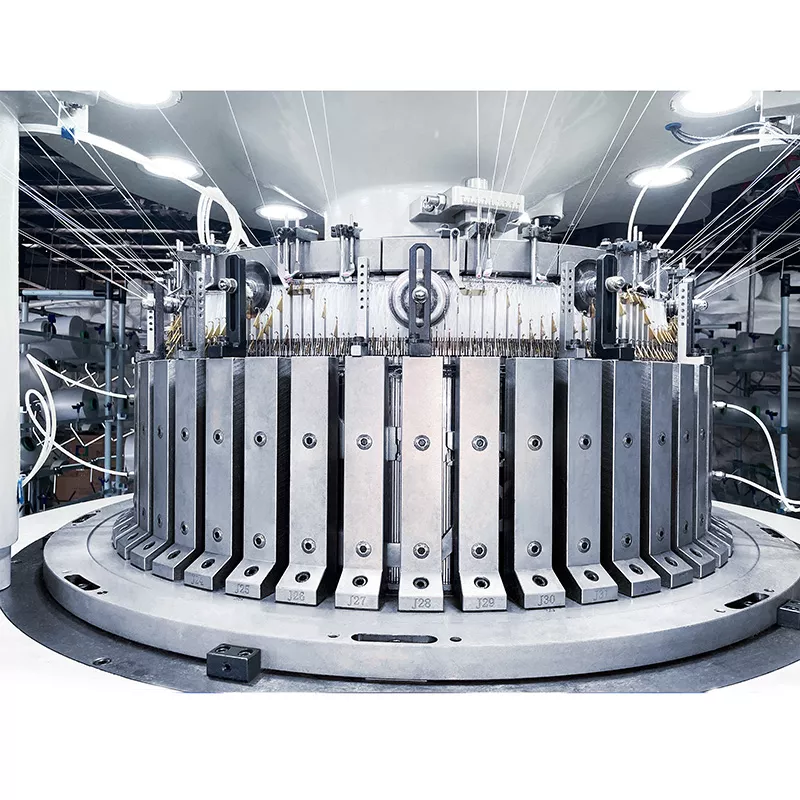

The textile industry’s rapid evolution demands machinery that can adapt to shifting trends and technical requirements. Hengye’s R&D team collaborates closely with clients to develop custom configurations, such as dual-function machines that switch between plush and flat-knit fabrics or specialized systems for fire-resistant automotive textiles. Their plush fabric knitting equipment supplier portfolio also includes retrofitting services, upgrading older models with smart sensors and IoT connectivity to enhance productivity.

For instance, a European automotive supplier partnered with Hengye to design a double pile circular knitting machine capable of producing ultra-fine pile fabrics for premium car interiors. The result? A 30% increase in output speed and a 20% reduction in defects, demonstrating Hengye’s ability to merge technical expertise with real-world problem-solving.

A Global Network Powered by Chinese Innovation

Today, Hengye’s machines operate in over 40 countries, supported by a network of regional service centers and multilingual technical teams. Their commitment to custom engineering has earned them partnerships with Fortune 500 companies and boutique designers alike, all united by a need for reliable, high-performance knitting solutions.

As the textile industry continues to embrace sustainability and automation, Hengye remains at the forefront, investing in AI-driven quality control and biodegradable yarn compatibility. For businesses seeking a circular knitting machine manufacturer that combines China’s manufacturing scale with bespoke innovation, Hengye offers more than machinery—it delivers a competitive edge.

Explore their range of artificial fur knitting machines and plush fabric knitting equipment today, and discover why Hengye is synonymous with precision, adaptability, and excellence in textile engineering.