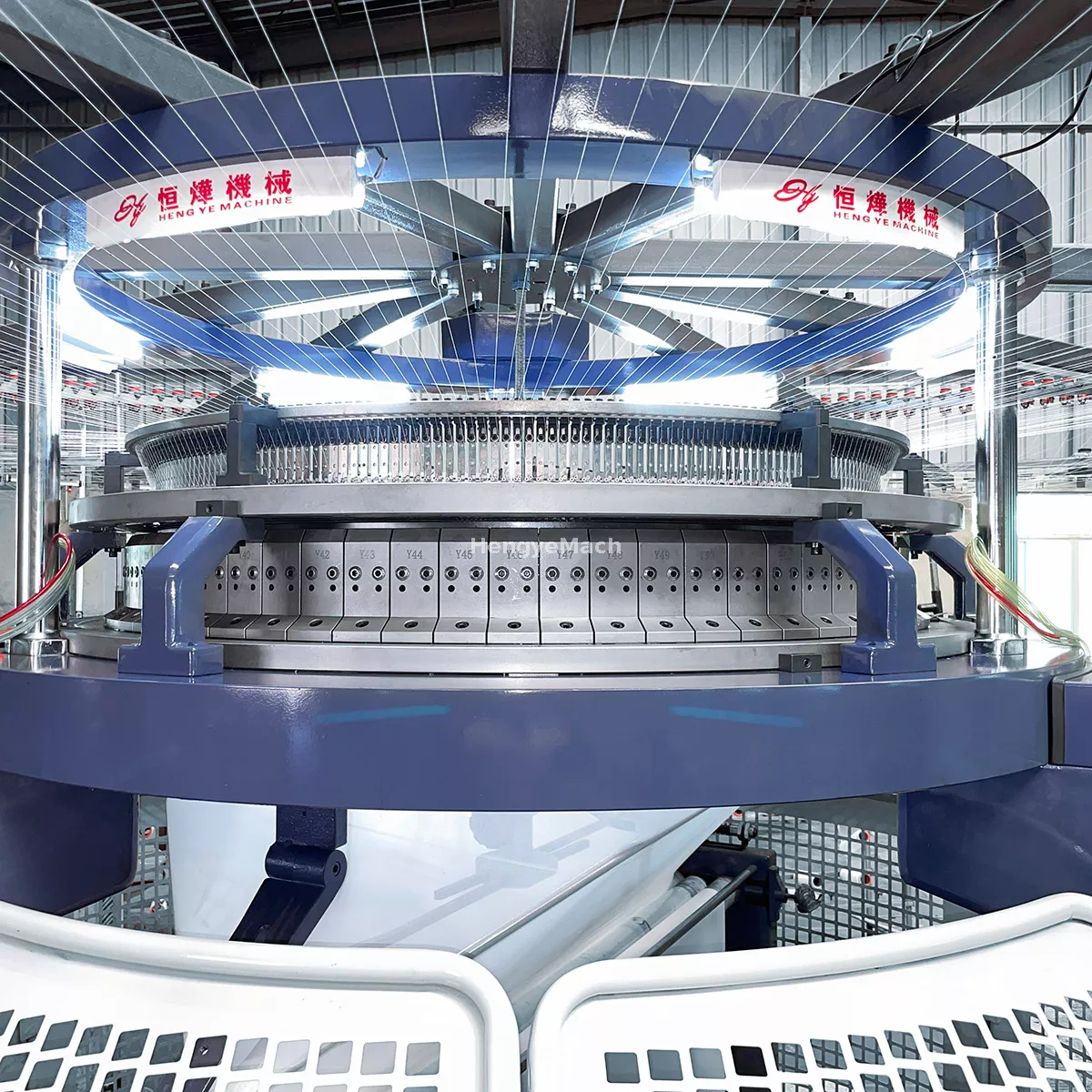

In the textile industry, where innovation and efficiency drive competitiveness, the demand for advanced double jersey circular knitting machines has never been higher. Manufacturers worldwide seek machines that blend speed, precision, and adaptability to meet evolving market demands. Among the leaders in this field, Hengye, a prominent open width knitting machine manufacturer in China, stands out for its commitment to quality, customization, and cutting-edge technology.

Hengye: Pioneering Knitting Machine Excellence in China

Based in China, Hengye has established itself as a trusted name in the global textile machinery sector. With a focus on research, development, and customer-centric solutions, the company specializes in producing high-efficiency knitting machines tailored to diverse applications. By leveraging China’s robust manufacturing ecosystem—including skilled labor, advanced infrastructure, and cost-effective supply chains—Hengye delivers machines that rival international standards while offering unmatched value.

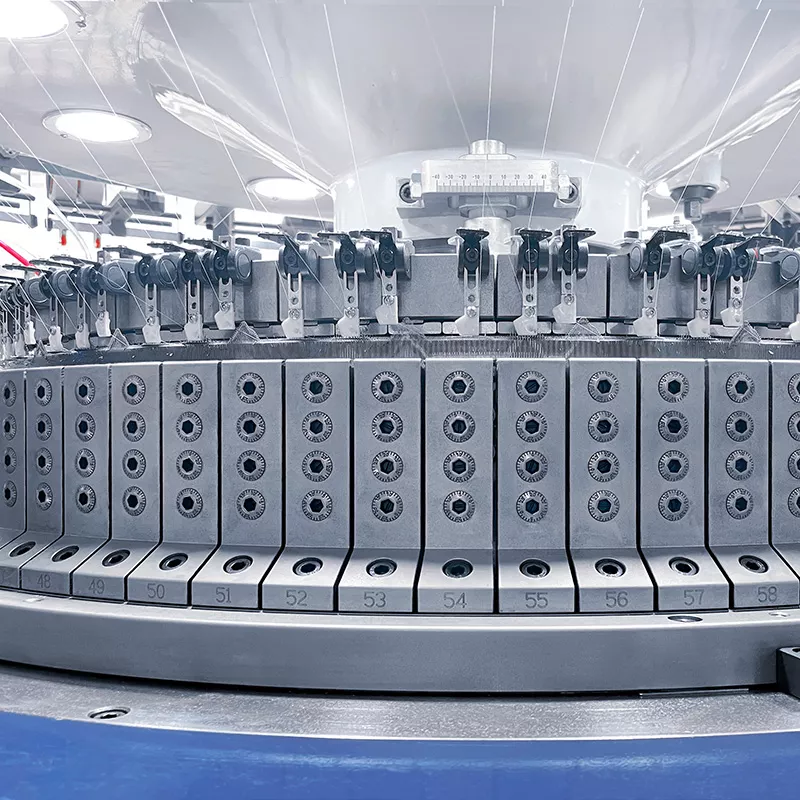

Double Jersey Circular Knitting Machines: Engineered for Versatility

At the heart of Hengye’s portfolio are its double jersey circular knitting machines, designed to produce seamless, high-quality fabrics with minimal waste. These machines feature dual-needle bed systems, advanced stitch control, and user-friendly interfaces, enabling operators to switch between patterns and fabrics effortlessly. Whether crafting lightweight jerseys, thick interlocks, or technical textiles, Hengye’s machines ensure consistency, durability, and speed—key factors for modern textile mills.

Open Width Knitting Machines: Redefining Fabric Production

Hengye’s open width knitting machines address a critical challenge in the industry: producing fabrics in their final width, eliminating the need for post-production cutting. This innovation reduces material waste, streamlines workflows, and lowers production costs. Equipped with precision tension control and automated edge-guiding systems, these machines are ideal for manufacturing woven-like fabrics, medical textiles, and automotive upholstery. By integrating open width technology, Hengye empowers manufacturers to stay ahead in niche markets.

Custom Double Jersey Fabric Machines: Tailored to Your Vision

Recognizing that every textile producer has unique requirements, Hengye excels in crafting custom double jersey fabric machines. From adjusting gauge sizes and cylinder diameters to integrating smart sensors and IoT connectivity, the company’s engineers collaborate closely with clients to design solutions that optimize productivity, energy efficiency, and product quality. Whether for small-batch artisanal production or large-scale industrial operations, Hengye’s custom machines deliver results that align with specific business goals.